Copper Bus Bar Applications in Electrical Systems

Copper bus bars are fundamental components in modern electrical systems, serving as critical conductors for power distribution in industries ranging from energy generation to transportation. Their high conductivity, durability, and adaptability make them indispensable in both low-voltage and high-voltage applications. This article explores the diverse applications of copper bus bars in electrical systems, supported by technical insights and real-world examples, to provide a holistic understanding of their role in contemporary engineering.

1. Technical Advantages of Copper Bus Bars

1.1 Superior Conductivity and Efficiency

Copper’s electrical conductivity (approximately 97% IACS) outperforms aluminum and other metals, minimizing energy loss during transmission. This property is crucial in high-current systems such as power substations, where even minor resistance reductions translate to significant cost savings over time.

1.2 Thermal and Mechanical Stability

Copper bus bars exhibit excellent thermal resistance, maintaining structural integrity under extreme temperatures. For instance, in switchgear installations, copper bus bars can withstand short-circuit currents exceeding 50 kA without deformation, ensuring system reliability2. Finite element analysis (FEM) studies further validate their performance in steady-state thermal conditions, accounting for solar radiation and convection effects.

1.3 Corrosion Resistance

Tinned or coated copper bus bars are widely used in harsh environments, such as marine or industrial settings, to prevent oxidation. This extends their lifespan and reduces maintenance costs compared to bare aluminum alternatives.

2. Key Applications in Electrical Systems

2.1 Power Distribution Networks

Copper bus bars are the backbone of electrical substations and switchgear. Their ability to handle high ampacity (current-carrying capacity) makes them ideal for connecting transformers, circuit breakers, and distribution panels. For example, TAIAN-ECOBAR’s cast-resin insulated busway systems, certified under IEC 62271 standards, are deployed in power plants to ensure efficient energy transfer with minimal losses.

2.2 Renewable Energy Systems

In solar and wind farms, copper bus bars facilitate the aggregation of power from photovoltaic panels or turbines. Their low resistance ensures maximum energy harvest, while their flexibility accommodates complex layouts in solar arrays.

2.3 Industrial Automation and Heavy Machinery

Manufacturing facilities rely on copper bus bars for motor control centers (MCCs) and CNC machines. A case study highlighted the use of copper bus bars in electrolysis rectifiers, where optimizing AC busbar voltage drop improved efficiency in copper refining processes.

2.4 Data Centers

Data centers demand uninterrupted power supply (UPS) systems with high fault tolerance. Copper bus bars in these setups ensure reliable power distribution to servers, reducing downtime risks. Their modular design also supports scalability in growing data infrastructures.

2.5 Electric Vehicles (EVs) and Battery Systems

EV battery packs utilize copper bus bars to interconnect lithium-ion cells, ensuring minimal energy loss during charging and discharging. Their lightweight yet robust design aligns with the automotive industry’s push for efficiency and durability1.

3. Design Considerations for Optimal Performance

3.1 Ampacity Calculation and Thermal Management

Accurate ampacity determination is critical to avoid overheating. Analytical algorithms, validated by FEM simulations, help engineers calculate allowable current ratings based on ambient temperature, convection modes, and radiation losses4. Forced-air cooling or heat sinks may be added in high-density applications like data centers.

3.2 Material and Coating Selection

Bare Copper: Suitable for indoor environments with controlled humidity.

Tinned Copper: Preferred in marine or corrosive industrial settings.

Silver-Plated Copper: Used in high-frequency applications to reduce skin effect losses.

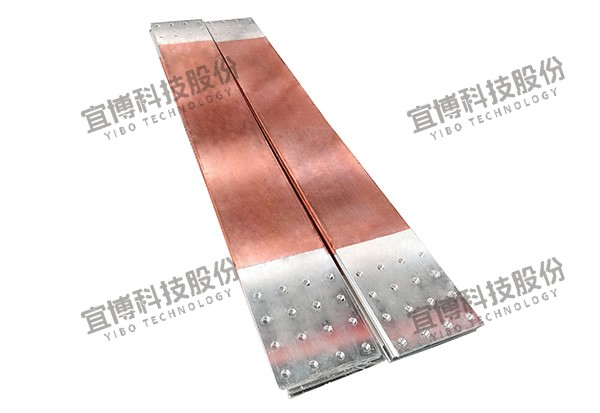

3.3 Mechanical Stress and Vibration Resistance

In transportation systems (e.g., railways), copper bus bars must endure vibrations. Rigid bus bars with bolted joints are often replaced by flexible laminated designs to absorb mechanical shocks.

4. Industry Case Studies

4.1 TAIAN-ECOBAR’s ASTA-Certified Busway Systems

TAIAN-ECOBAR’s medium-voltage busway products, compliant with IEC 62271-201, demonstrate how copper bus bars enhance grid reliability. Their cast-resin insulation technology reduces partial discharge risks, making them a preferred choice in Asian power distribution networks3.

4.2 Copper Bus Bars in Electrolysis Rectifiers

A study on copper electrolysis rectifiers revealed that optimizing busbar geometry reduced voltage drop by 15%, significantly lowering energy consumption in refineries. This highlights the importance of precision engineering in industrial applications.

5. Future Trends and Innovations

5.1 Smart Monitoring Systems

Integration of IoT sensors enables real-time monitoring of busbar temperature and resistance, predicting failures before they occur. This aligns with Industry 4.0’s push for predictive maintenance.

5.2 Sustainable Manufacturing

Recycled copper bus bars are gaining traction, driven by circular economy initiatives. Suppliers in China now offer eco-friendly options with 95% recycled content, reducing the carbon footprint of electrical projects.

5.3 High-Frequency Applications

With the rise of 5G and renewable microgrids, copper bus bars are being redesigned to minimize electromagnetic interference (EMI), ensuring compatibility with sensitive electronic equipment.

Conclusion

From powering megacities to enabling green energy transitions, copper bus bars are indispensable in modern electrical systems. Their versatility, combined with advancements in materials science and smart technologies, ensures they will remain at the forefront of electrical engineering. For engineers and procurement managers, understanding these applications and design principles is key to optimizing system performance and cost-efficiency.