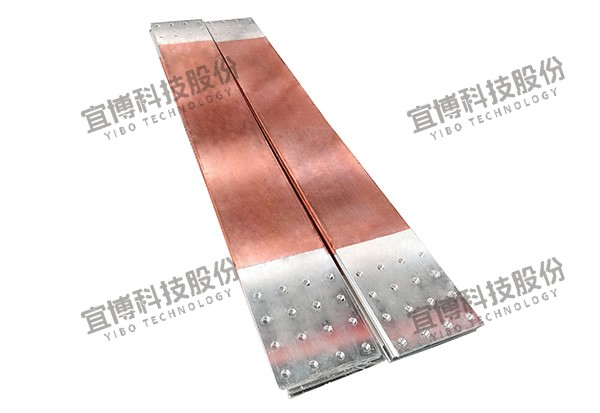

Customized Processing of Copper Bus Bar for the Electrolysis Industry

In the electrolysis industry, efficient and reliable power transmission is crucial for the optimal performance of electrolysis processes. Copper bus bars play a vital role in this regard, serving as essential components for conducting high currents to electrolysis cells and other critical equipment. However, the specific requirements of different electrolysis systems demand customized processing of copper bus bars to ensure they meet the unique operational demands of the industry. Qingdao Yibo Technology Co., Ltd. specializes in providing tailored copper bus bar processing services that cater to the distinct needs of the electrolysis sector, ensuring enhanced efficiency and reliability in electrolysis operations.

Understanding the Unique Needs of the Electrolysis Industry

Electrolysis processes involve the passage of large electrical currents through electrolyte solutions to drive chemical reactions. This requires copper bus bars that can handle high current loads, operate under specific temperature conditions, and resist corrosion in the presence of electrolytes. The layout and design of electrolysis cells also vary among different facilities, necessitating copper bus bars with customized shapes, sizes, and configurations to ensure proper integration and optimal performance within the electrolysis system. Recognizing these unique requirements, Qingdao Yibo Technology Co., Ltd. works closely with electrolysis industry clients to develop customized copper bus bar solutions that address their specific operational challenges and enhance the overall efficiency of their electrolysis processes.

Customized Design and Engineering

The team at Qingdao Yibo Technology Co., Ltd. begins by thoroughly understanding the client's electrolysis system specifications, including the electrical parameters, cell layout, and environmental conditions. Based on this information, our experienced engineers utilize advanced design software to create customized copper bus bar designs that precisely match the requirements of the electrolysis equipment. Factors such as current capacity, voltage drop, heat dissipation, and mechanical strength are carefully considered during the design phase to ensure the copper bus bars can withstand the demanding conditions of the electrolysis process while providing reliable power transmission.

Specialized Material Selection and Treatment

For the electrolysis industry, the choice of copper material and its treatment is critical to ensuring the longevity and performance of copper bus bars. Qingdao Yibo Technology Co., Ltd. offers a range of high-purity copper materials with excellent electrical conductivity and corrosion resistance properties. Additionally, we provide various surface treatment options, such as insulation coatings and anti-corrosion treatments, to further enhance the bus bars' durability in the harsh electrolysis environment. These treatments help prevent degradation of the copper bus bars due to exposure to electrolytes and other corrosive substances commonly found in electrolysis operations.

Precision Manufacturing and Processing Techniques

Equipped with state-of-the-art manufacturing equipment and skilled craftsmanship, Qingdao Yibo Technology Co., Ltd. employs precision machining, bending, and welding techniques to produce customized copper bus bars with tight tolerances and high-quality finishes. Our advanced CNC machining centers and laser cutting machines ensure precise dimensional accuracy, while our specialized bending equipment allows us to create complex shapes and configurations without compromising the integrity of the copper material. The welding and brazing processes used to assemble multi-component copper bus bar systems are meticulously controlled to ensure strong, reliable connections that can withstand the high currents and mechanical stresses encountered in electrolysis applications.

Rigorous Quality Control for Electrolysis Applications

Given the critical nature of copper bus bars in electrolysis systems, Qingdao Yibo Technology Co., Ltd. maintains a stringent quality control system specifically tailored to the demands of the electrolysis industry. Every customized copper bus bar undergoes comprehensive testing and inspection procedures to verify its electrical, mechanical, and chemical performance. Tests such as electrical conductivity measurements, withstand voltage tests, corrosion resistance assessments, and mechanical strength evaluations are conducted to ensure the bus bars meet the highest quality standards and can reliably perform in the challenging electrolysis environment. Only after passing these rigorous quality checks are the customized copper bus bars approved for installation in the client's electrolysis facility.

Applications in the Electrolysis Industry

The customized copper bus bars produced by Qingdao Yibo Technology Co., Ltd. find widespread applications in various electrolysis processes, including but not limited to:

- Electrolytic Metal Refining: In the refining of metals such as copper, aluminum, and zinc, where high-purity metal cathodes are produced through electrolysis, our customized copper bus bars ensure efficient power delivery to the electrolysis cells, contributing to improved metal purity and refining efficiency.

- Chlor-Alkali Electrolysis: In the production of chlorine and sodium hydroxide, critical chemicals for the pulp and paper, textiles, and soap industries, our copper bus bars are designed to withstand the corrosive conditions of chlor-alkali electrolysis cells and provide reliable power transmission for continuous production operations.

- Electroplating: For electroplating processes where precise control of current distribution is essential for achieving uniform coating thickness and quality, our customized copper bus bars help optimize current flow to the electroplating tanks, enhancing the overall plating performance and product quality.

- Water Electrolysis for Hydrogen Production: As the demand for hydrogen as a clean energy carrier grows, electrolysis of water is gaining attention. Our customized copper bus bars are suitable for use in water electrolysis systems, ensuring efficient power supply to the electrolyzers and supporting the production of high-purity hydrogen for energy applications.

Collaboration and Project Management

Qingdao Yibo Technology Co., Ltd. recognizes the importance of close collaboration with electrolysis industry clients throughout the entire project lifecycle. From the initial inquiry and design phase to production, installation, and after-sales support, our dedicated project management team works hand in hand with clients to ensure smooth project execution and timely delivery of customized copper bus bar solutions. We maintain open and transparent communication channels to address any questions or concerns that may arise during the project and make necessary adjustments to meet the client's evolving requirements.

Why Choose Qingdao Yibo Technology Co., Ltd. for Electrolysis Industry Customized Copper Bus Bar Processing?

- Industry-Specific Expertise: Our in-depth understanding of the electrolysis industry's operational challenges and requirements enables us to provide customized copper bus bar solutions that are specifically designed to enhance the performance and reliability of electrolysis systems.

- Advanced Manufacturing Capabilities: With cutting-edge production equipment and skilled technical personnel, we can produce customized copper bus bars with complex shapes, precise dimensions, and high-quality finishes to meet the exact specifications of your electrolysis equipment.

- Tailored Material Solutions: We offer a wide range of copper materials and specialized treatments to ensure your copper bus bars possess the necessary electrical conductivity, corrosion resistance, and mechanical strength for long-term reliable operation in the electrolysis environment.

- Comprehensive Quality Assurance: Our rigorous quality control system, specifically adapted for the electrolysis industry, guarantees that every customized copper bus bar we deliver meets the highest standards of performance and safety, reducing the risk of equipment failures and downtime in your electrolysis operations.

- Dedicated Customer Support: Our professional team is committed to providing exceptional customer service and support throughout your project. We are available to assist you with technical inquiries, design optimization, and any other needs you may have to ensure your complete satisfaction with our customized copper bus bar processing services.

In the electrolysis industry, where reliable power transmission is fundamental to process efficiency and product quality, customized processing of copper bus bars by Qingdao Yibo Technology Co., Ltd. offers a proven solution to meet the unique demands of your electrolysis systems. By choosing our company as your trusted partner for customized copper bus bar processing, you can enhance the performance, reliability, and longevity of your electrolysis operations, ultimately leading to improved production outcomes and cost savings. Contact Qingdao Yibo Technology Co., Ltd. today to discuss your electrolysis industry copper bus bar customization needs and discover how our expertise and advanced manufacturing capabilities can benefit your facility.