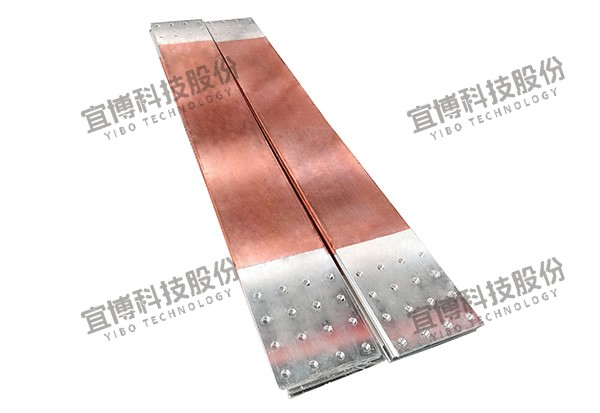

High conductivity aluminum bus bar

High Conductivity Aluminum Busbars: Powering Modern Electrical Systems

In today’s rapidly advancing technological landscape, efficient and reliable electrical power distribution is crucial across various industries. High conductivity aluminum busbars have emerged as a vital component in meeting these demands, offering a range of advantages that make them an ideal choice for numerous applications.

Understanding High Conductivity Aluminum Busbars

A busbar is a electrical conductor that serves as a central point for distributing electrical power to multiple circuits or devices within a system. High conductivity aluminum busbars are specifically designed to maximize the efficient flow of electrical current. Made from high-purity aluminum alloys, these busbars exhibit exceptional electrical conductivity, typically reaching up to 62% of the International Annealed Copper Standard (IACS), which is remarkable for non-copper materials.

The high conductivity of these aluminum busbars is achieved through careful material selection and advanced manufacturing processes. The aluminum alloys used are engineered to minimize resistivity, ensuring minimal energy loss during power transmission. This makes them highly efficient in conducting electricity over long distances or within complex electrical systems.

Applications Across Industries

The versatility of high conductivity aluminum busbars allows them to be utilized in a wide array of industries. In power generation facilities, such as substations and power plants, they play a critical role in transmitting high currents from generators to transformers and other electrical equipment. Their robust construction and excellent conductivity ensure stable and reliable power distribution, even under demanding operating conditions.

In industrial manufacturing settings, these busbars are integral to machinery and production lines that require substantial electrical power. They provide a secure and efficient means of connecting various electrical components, enabling smooth operations and minimizing downtime caused by power supply issues. For example, in the automotive manufacturing industry, high conductivity aluminum busbars are used in automated assembly lines to power robotic arms and other equipment that demand precise and consistent electrical supply.

The renewable energy sector has also benefited significantly from high conductivity aluminum busbars. In solar power installations and wind farms, these busbars facilitate efficient power collection and transmission from renewable energy sources to the grid. Their ability to handle fluctuating currents and withstand outdoor environmental conditions makes them well-suited for this growing industry. As the world shifts towards sustainable energy solutions, the demand for reliable and high-performance busbars is expected to rise further.

Advantages Over Traditional Materials

Compared to traditional materials like copper, high conductivity aluminum busbars offer several advantages. One of the most notable is their lower weight. Aluminum is approximately 70% lighter than copper, which makes installation and transportation more manageable, especially in large-scale electrical systems. This weight reduction also translates to cost savings in structural supports and infrastructure required for heavy copper busbars.

Cost-effectiveness is another significant advantage. Aluminum is generally more affordable than copper, making high conductivity aluminum busbars a more economical choice for many applications. This is particularly beneficial for large industrial projects and infrastructure developments where material costs can be substantial. Additionally, the price of aluminum tends to be more stable than copper, providing better cost predictability for long-term projects.

High conductivity aluminum busbars also exhibit excellent corrosion resistance. When exposed to atmospheric conditions, aluminum forms a protective oxide layer on its surface, which prevents further corrosion. This natural resistance to corrosion extends the service life of the busbars, reducing maintenance costs and the frequency of replacements. In harsh environments, such as coastal areas or industrial settings with high humidity and chemical exposure, this corrosion resistance is invaluable.

Design and Customization Options

One of the key strengths of high conductivity aluminum busbars is their flexibility in design and customization. They can be manufactured in various shapes and sizes to accommodate specific electrical system layouts and requirements. Common configurations include flat bars, rectangular bars, and tubular shapes, each offering unique advantages in terms of current carrying capacity, mechanical strength, and installation convenience.

Customization extends beyond physical dimensions to include features such as insulation coatings, terminations, and connections. Insulation materials can be applied to prevent electrical discharges and ensure safe operation in close proximity to other components. Terminations and connections can be designed to facilitate easy and secure integration with other electrical equipment, such as circuit breakers, switches, and transformers. This level of customization allows electrical engineers and system designers to optimize the performance and reliability of their electrical systems.

Installation and Maintenance Considerations

Proper installation is crucial for the optimal performance and longevity of high conductivity aluminum busbars. It is essential to follow manufacturer guidelines and industry best practices to ensure secure and efficient connections. This includes using appropriate tools and techniques for cutting, bending, and terminating the busbars. Additionally, considerations such as thermal expansion and contraction, as well as mechanical stress, should be taken into account during installation to prevent damage and ensure stable operation over time.

Regular maintenance is another important aspect of ensuring the reliable functioning of aluminum busbars. Routine inspections should be conducted to check for signs of wear, corrosion, or loose connections. Simple maintenance tasks, such as cleaning the busbar surfaces, tightening connections, and applying protective coatings, can significantly extend their service life. In industrial environments with high levels of dust, moisture, or chemical contaminants, more frequent maintenance may be necessary to mitigate the risk of electrical failures.

Selecting the Right Supplier

When sourcing high conductivity aluminum busbars, it is vital to choose a reputable and experienced supplier. A reliable supplier should possess the necessary certifications and quality assurance credentials, such as ISO standards and industry-specific certifications. This ensures that the busbars meet stringent quality and safety requirements.

Evaluating a supplier’s production capabilities is also crucial. They should have advanced manufacturing facilities and quality control processes in place to consistently produce high-quality busbars. Requesting product samples for testing and inspection can provide valuable insights into the actual performance and characteristics of the busbars.

Furthermore, consider the supplier’s customer service and support. A good supplier should be able to provide technical assistance, offer customization options, and deliver products on time. Reading customer reviews and seeking recommendations from industry peers can help identify suppliers with a proven track record of reliability and customer satisfaction.

Future Trends and Outlook

As technology continues to advance and electrical power demands increase, the demand for high conductivity aluminum busbars is expected to grow. In the renewable energy sector, the expansion of solar and wind power installations will drive the need for efficient and cost-effective power distribution solutions. High conductivity aluminum busbars are well-positioned to meet this demand due to their excellent electrical performance and suitability for outdoor applications.

In the realm of electric vehicles (EVs), high conductivity aluminum busbars are finding applications in charging infrastructure and within the vehicles themselves. As EV adoption rates rise, the market for busbars that can handle high currents and support fast charging will expand. This presents new opportunities for manufacturers and suppliers of aluminum busbars to develop specialized products for the automotive industry.

Furthermore, ongoing research and development efforts are focused on improving the conductivity and performance of aluminum alloys used in busbars. Innovations in material science and manufacturing technologies are likely to lead to even higher conductivity levels and enhanced mechanical properties, further solidifying the position of aluminum busbars in the electrical power distribution market.

In conclusion, high conductivity aluminum busbars are a vital component in modern electrical systems, offering a range of benefits that make them indispensable across various industries. Their high conductivity, lightweight nature, cost-effectiveness, and durability have made them a preferred choice for power distribution applications. As technology evolves and new challenges emerge in the electrical power sector, high conductivity aluminum busbars are poised to play an increasingly important role in meeting the growing demands for efficient and reliable power transmission solutions.