Corrosion-Resistant Aluminum Busbars: Powering Modern Electrical Systems with Stability

In today’s complex electrical systems, the reliability and longevity of components are critical. Corrosion-resistant aluminum busbars have emerged as a preferred choice for power distribution in various industries due to their unique properties and performance advantages. This article delves into the characteristics, applications, and benefits of corrosion-resistant aluminum busbars.

The Inherent Corrosion Resistance of Aluminum Busbars

Aluminum busbars are inherently corrosion-resistant. When exposed to air, aluminum forms a thin, dense oxide layer on its surface. This oxide layer acts as a protective barrier, preventing further oxidation and corrosion of the underlying aluminum substrate. This natural corrosion resistance makes aluminum busbars suitable for use in diverse environments, from indoor industrial facilities to outdoor installations exposed to harsh weather conditions

Common Materials and Enhanced Corrosion-Resistance Technologie

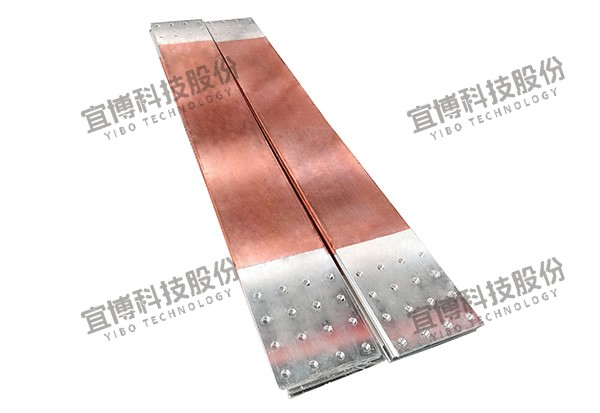

Common Alloy Materials: Several aluminum alloys are widely used for corrosion-resistant aluminum busbars. For instance, 6061-T6 aluminum alloy is known for its excellent balance of strength and corrosion resistance. Its primary alloying elements are magnesium and silicon, which provide good mechanical properties and resistance to atmospheric corrosion, making it suitable for general industrial environments. The 6063-T6 alloy, characterized by its excellent extrudability and corrosion resistance, is commonly used in applications requiring complex cross-sectional shapes, such as architectural and transportation electrical systems. The 5052 aluminum alloy stands out for its exceptional corrosion resistance in marine and chemical environments, making it ideal for use in ships, offshore platforms, and other highly corrosive settings

.

Surface Treatment Technologies: To further enhance corrosion resistance, various surface treatment methods are employed. Tin-plating is a common technique where a thin layer of tin is applied to the surface of aluminum busbars via electroplating or immersion plating. The tin layer provides additional protection against oxidation and corrosion, effectively preventing the deterioration of the oxide layer in humid or polluted environments. It also mitigates the risk of galvanic corrosion when aluminum busbars come into contact with other metals. Epoxy coating is another effective surface treatment. Epoxy-coated busbars offer both insulation and environmental protection, eliminating the need for external insulation materials while shielding the busbars from corrosive elements in the environment

Superior Performance in Diverse Applications

Power Generation and Transmission Sector: In power plants and substations, corrosion-resistant aluminum busbars serve as critical conductors for power transmission and distribution. Their low resistance and excellent conductivity enable efficient transfer of electricity from generators or transformers to the distribution system. Thanks to their corrosion resistance, they ensure stable performance in high-humidity, polluted, or harsh environments, significantly extending their lifespan and reducing maintenance needs

Transportation Industry: In railways and ships, corrosion-resistant aluminum busbars play a vital role in power distribution systems. The transportation industry demands efficient and durable power transmission systems. These busbars can withstand long-term operation in humid and saltwater-corrosive environments, ensuring stable power supply to railway vehicles and ship electrical systems. For electric vehicles, corrosion-resistant aluminum busbars are used in battery management systems and power distribution devices. They transmit power between the battery pack and the power system efficiently and stably, while their protective layers resist corrosion in high-temperature and high-humidity environments, enhancing the reliability of electric vehicle systems

Telecommunications Industry: Communication equipment requires stable electrical connections to ensure uninterrupted operation. Corrosion-resistant aluminum busbars meet this demand by providing reliable connections. As communication equipment becomes more complex and power-intensive, corrosion-resistant aluminum busbars become the ideal choice. Their protective layers enhance the durability of aluminum busbars, allowing them to maintain low resistance and high efficiency in humid environments, thereby ensuring the stability and efficiency of communication systems

Industrial Manufacturing Sector: In factories and manufacturing plants, corrosion-resistant aluminum busbars are widely used for power distribution in machinery and production lines. They can withstand corrosive substances such as dust, chemicals, and moisture found in industrial environments, ensuring stable power supply to equipment and minimizing production interruptions caused by busbar failures. This, in turn, improves production efficiency and product quality

Cost and Environmental Advantages

Cost Savings: Aluminum itself is relatively inexpensive compared to other conductive metals like copper. Choosing corrosion-resistant aluminum busbars reduces initial material costs. Additionally, their lightweight nature lowers transportation and installation costs. While surface treatment processes may increase costs slightly, the extended service life and reduced maintenance requirements of corrosion-resistant aluminum busbars result in significant cost savings over the long term

Environmental Benefits: Aluminum is a highly recyclable material. Corrosion-resistant aluminum busbars can be recycled and reused at the end of their life cycle, aligning with sustainable development goals and reducing the environmental impact of electrical systems. Their natural corrosion resistance also minimizes the need for frequent replacements, reducing waste generation and resource consumption

In summary, corrosion-resistant aluminum busbars play a pivotal role in modern electrical systems. Their excellent corrosion resistance, coupled with advantages such as lightweight design, good conductivity, and cost-effectiveness, make them indispensable in various industries. As technology advances and environmental requirements become stricter, corrosion-resistant aluminum busbars will continue to evolve and enhance, offering more reliable and efficient power distribution solutions to meet the growing demands of industrial and social development.