Custom Size Aluminum Busbars: Tailoring Power Solutions for Diverse Applications

Custom Size Aluminum Busbars: Tailoring Power Solutions for Diverse Applications

In the intricate realm of electrical systems, the demand for precise and efficient power distribution solutions continues to grow across various industries. Custom size aluminum busbars have emerged as versatile and reliable conductors that cater to the unique requirements of different electrical setups. This article explores the significance, applications, advantages, and considerations of custom size aluminum busbars.

Overview of Custom Size Aluminum Busbars

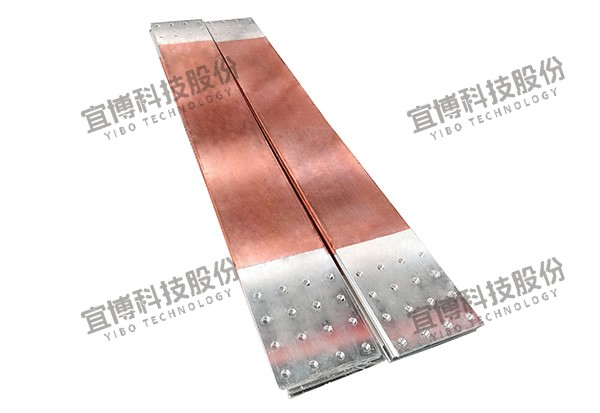

Custom size aluminum busbars are conductive bars made from high-conductivity aluminum alloys, specifically tailored to meet the exact dimensions and specifications required for particular electrical applications. These busbars can be manufactured in a wide range of sizes, shapes, and configurations, from simple flat bars to complex multi-segment designs, to ensure optimal performance in diverse electrical systems.

Applications Across Industries

Industrial Manufacturing

In industrial settings, machinery and equipment often have unique power distribution needs. Custom size aluminum busbars can be designed to fit the specific layouts and current requirements of manufacturing plants, ensuring efficient power delivery to various machines and production lines. Their ability to handle high currents and withstand industrial environments makes them ideal for powering heavy-duty equipment and maintaining uninterrupted operations.

Power Generation and Distribution

Within power plants and substations, custom size aluminum busbars play a crucial role in transmitting electricity from generators to transformers and other electrical devices. By tailoring the busbars to the exact specifications of the power generation and distribution infrastructure, energy losses can be minimized, and the overall efficiency of the electrical system can be enhanced.

Transportation

In the transportation sector, electric vehicles (EVs) and hybrid vehicles require precise power distribution systems. Custom size aluminum busbars can be engineered to meet the spatial constraints and high-current demands of EV battery management systems and electric motors. Additionally, in railway systems, custom busbars ensure reliable power supply to train control systems and signaling equipment.

Performance Advantages

High Conductivity

Aluminum is renowned for its excellent electrical conductivity, making custom size aluminum busbars highly efficient in transmitting electrical current. With conductivity levels reaching up to 62% of the International Annealed Copper Standard (IACS), these busbars ensure minimal energy loss during power transmission, resulting in more efficient electrical systems and reduced operational costs.

Mechanical Strength and Durability

Aluminum busbars possess sufficient mechanical strength to withstand the rigors of industrial and commercial applications. They can support their own weight and resist deformation caused by mechanical stresses, vibrations, and temperature fluctuations. This durability ensures long-term reliability and reduces the need for frequent maintenance or replacement.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer on its surface when exposed to air, providing inherent resistance to corrosion. For applications in harsh environments or those prone to moisture and chemical exposure, custom size aluminum busbars can be further treated with coatings or alloys to enhance their corrosion resistance, ensuring stable performance over an extended period.

Thermal Management

Aluminum has good thermal conductivity, allowing custom size busbars to effectively dissipate heat generated during operation. This efficient heat management prevents overheating, which can lead to performance degradation or equipment failure. In high-current applications, the ability to maintain optimal operating temperatures is crucial for the longevity and safety of electrical systems.

Considerations for Custom Size Aluminum Busbars

Material Selection

The choice of aluminum alloy is critical in determining the performance characteristics of custom size busbars. Common alloys used include 6061-T6, known for its balance of strength and conductivity, and 6063-T6, which offers excellent extrudability and corrosion resistance. The specific requirements of the application, such as current-carrying capacity, mechanical stress, and environmental conditions, should guide the selection of the appropriate alloy.

Design and Specifications

Accurate design and precise specifications are essential when ordering custom size aluminum busbars. Factors such as busbar length, width, thickness, shape, and connection points must be clearly defined to ensure proper integration with the electrical system. Electrical engineers should provide detailed technical drawings and specifications to the manufacturer to guarantee the busbars meet the required performance standards.

Manufacturing Capabilities

Selecting a manufacturer with advanced manufacturing capabilities and expertise in custom aluminum busbar production is vital. Reputable manufacturers should have the equipment and technical know-how to produce busbars with tight tolerances and high-quality finishes. They should also adhere to industry standards and quality control processes to ensure consistent product quality.

Testing and Certification

Before installation, custom size aluminum busbars should undergo rigorous testing and certification to verify their electrical, mechanical, and safety performance. Tests may include conductivity measurements, mechanical stress tests, dielectric strength testing, and corrosion resistance evaluations. Certifications from recognized standards organizations provide assurance that the busbars meet the necessary requirements for their intended applications.

Future Trends and Innovations

Advanced Manufacturing Techniques

As manufacturing technologies continue to evolve, custom size aluminum busbars are benefiting from improved production methods. Advanced CNC machining, laser cutting, and 3D printing technologies are enabling even greater precision and complexity in busbar designs. These techniques allow for the creation of highly customized busbars with intricate geometries that were previously difficult or impossible to achieve.

Smart Busbar Systems

The integration of smart technologies into custom size aluminum busbars is an emerging trend. By incorporating sensors and monitoring systems, busbars can provide real-time data on electrical parameters such as current, voltage, and temperature. This data can be used for predictive maintenance, fault detection, and optimizing energy efficiency in electrical systems.

Sustainability and Recycling

With increasing focus on sustainability, the recyclability of aluminum busbars is a significant advantage. Aluminum is a highly recyclable material, and custom size busbars can be recycled at the end of their service life with minimal loss of material properties. Additionally, manufacturers are adopting more sustainable production practices and using recycled aluminum content in their busbar products to reduce the environmental impact.

Conclusion

Custom size aluminum busbars offer tailored power distribution solutions that are essential for the efficient and reliable operation of electrical systems across various industries. Their high conductivity, mechanical strength, corrosion resistance, and thermal management properties make them suitable for a wide range of applications. By carefully considering material selection, design specifications, manufacturing capabilities, and testing requirements, engineers and designers can ensure optimal performance and longevity of custom size aluminum busbars. As technology advances and sustainability becomes increasingly important, custom size aluminum busbars will continue to play a crucial role in meeting the evolving power distribution needs of our modern world.