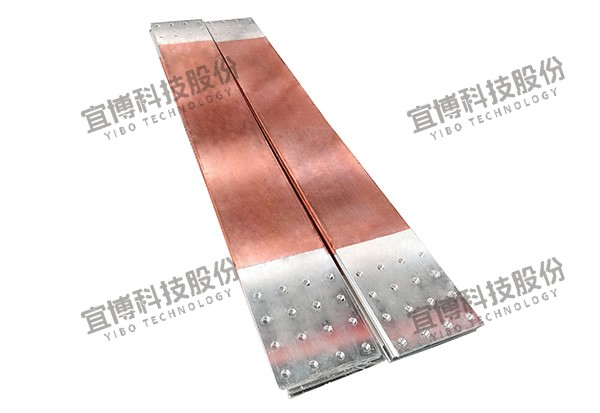

Pure Aluminum Bus Bar: The Lightweight Powerhouse Revolutionizing Electrical Systems

In today’s energy-intensive world, Pure Aluminum Bus Bars (≥99.6% Al) are transforming power distribution with unparalleled efficiency. Unlike copper-clad alternatives, pure aluminum delivers exceptional performance where weight, cost, and corrosion resistance matter most. Here’s why engineers globally are switching to this advanced solution:

Superior Conductivity-to-Weight Ratio

With 61% IACS conductivity at just 30% of copper’s weight, aluminum bus bars slash structural loads in applications like EV batteries and solar farms. Tesla’s battery packs use aluminum bus bars to achieve 15% weight reduction per kWh capacity.

Extreme Environmental Resilience

Anodized pure aluminum withstands:

1,000+ hours salt spray tests (ASTM B117)

UV radiation degradation

Chemical exposure in industrial settings

Ideal for offshore wind farms and coastal substations.

Thermal Management Mastery

Aluminum’s 229 W/m·K thermal conductivity dissipates heat 30% faster than copper during fault currents. Combined with a -50°C to 150°C operational range, it prevents hotspots in high-density data centers.

Lifecycle Cost Savings

At 40% lower material cost than copper plus zero maintenance requirements, facilities report ROI within 18 months. Mining giant Rio Tinto cut substation costs by $2.1M using aluminum bus bars.

Critical Applications Driving Adoption

Industry Use Case Performance Benefit

EV/Batteries Cell-to-pack connections 20% weight reduction → extended range

Renewables Solar combiner boxes Corrosion resistance in desert/coastal sites

Data Centers Server rack power distribution 40°C lower temps vs copper

Industrial CNC machine power feeds Vibration resistance + EMI shielding

⚙️ Installation & Compliance Insights

Bending Rules: Minimum bend radius = 2x thickness (avoid annealing)

Certifications: UL 891/ IEC 61439-1 compliant designs

Grounding: Use dedicated aluminum grounding bars (NEC Article 250.64(F))

Joining: Ultrasonic welding preferred over bolting for resistance <5μΩ

Sustainability Impact: Recycled aluminum bus bars consume 95% less energy than new production. Siemens reports 8.5 tons CO2 reduction per 1km bus duct installation.

Future Outlook

With aluminum conductivity enhancements hitting 63% IACS in R&D labs (Pacific Northwest National Laboratory, 2023), expect 15% smaller cross-sections by 2026. The global aluminum bus bar market will reach $24.7B by 2030 (Grand View Research), driven by hyperscale data centers and green hydrogen projects.