Copper-Aluminum Transition Material: A Game - Changer in Electrical Systems

Copper-Aluminum Transition Material: A Game - Changer in Electrical Systems

In the ever - evolving landscape of electrical systems and power transmission, the materials used play a pivotal role in determining efficiency, reliability, and longevity. Among the innovative materials that have gained significant traction is copper - aluminum transition material. This article explores the ins and outs of copper - aluminum transition material, shedding light on its composition, advantages, applications, and the impact it has on various industries.

What is Copper - Aluminum Transition Material?

Copper - aluminum transition material is a specialized metallurgical product designed to provide a seamless interface between copper and aluminum components in electrical systems. It combines the favorable properties of both copper and aluminum, addressing the inherent challenges that arise when these two metals are connected directly. Through advanced bonding techniques, such as explosion welding, roll - bonding, or co - extrusion, a stable metallurgical bond is formed between copper and aluminum layers.

The Need for Copper - Aluminum Transition Material

Copper and aluminum are both widely used in electrical applications due to their excellent electrical conductivity. However, they have different electrochemical properties, leading to issues like galvanic corrosion when in direct contact. When copper and aluminum are connected directly in an electrical system, a galvanic cell is created. Aluminum, being more electrochemically active than copper, acts as the anode and tends to corrode. This corrosion can increase the electrical resistance at the connection point over time, resulting in overheating, energy losses, and even potential equipment failures. Copper - aluminum transition material eliminates this problem by acting as a compatible intermediary between the two metals.

Composition and Types of Copper - Aluminum Transition Material

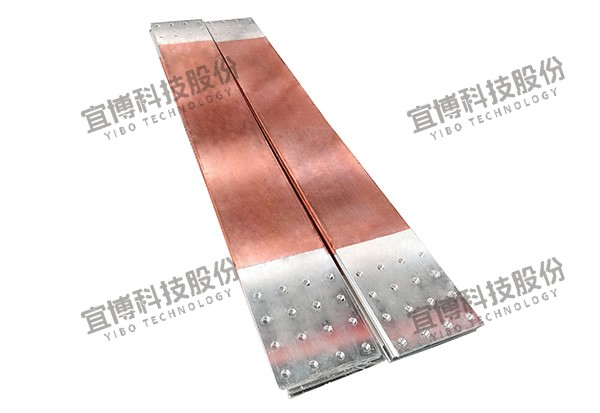

Bimetallic Sheets and Plates

These are made by bonding copper and aluminum layers together. The thickness of each layer can be varied depending on the specific application requirements. Bimetallic sheets and plates offer excellent electrical conductivity, good corrosion resistance, and the lightweight advantages of aluminum. They are widely used in the manufacturing of busbars, electrical connectors, and other electrical components.

Clad Wires and Rods

Copper - aluminum clad wires and rods consist of a copper layer clad over an aluminum core. This type of transition material combines the high - strength and good - conductivity properties of copper with the lightweight and cost - effective nature of aluminum. They are commonly used in power transmission lines, electrical cables, and other applications where flexibility and strength are important.

Advantages of Copper - Aluminum Transition Material

Excellent Electrical Performance

Copper - aluminum transition material provides a stable and low - resistance electrical connection. It prevents the formation of oxide layers and corrosion that can occur at copper - aluminum interfaces, ensuring efficient current transfer and minimizing energy losses in electrical systems.

Corrosion Resistance

The unique metallurgical bond in copper - aluminum transition material creates a barrier against galvanic corrosion. This enhances the durability and service life of electrical components, reducing maintenance requirements and the risk of equipment failures.

Lightweight and Cost - Effective

Compared to pure copper components, copper - aluminum transition material offers a lightweight alternative without compromising on electrical performance. This makes it easier to handle and install, especially in applications where weight is a critical factor. Additionally, the use of aluminum as the base material helps reduce costs, making it a more economical choice for large - scale electrical installations.

Versatility and Adaptability

Copper - aluminum transition material is available in various forms, such as sheets, plates, wires, and rods. This versatility allows it to be used in a wide range of electrical applications, from power generation and transmission to industrial and commercial electrical systems. It can be easily fabricated and processed using standard metalworking techniques, making it convenient for manufacturers and engineers to incorporate into their designs.

Applications of Copper - Aluminum Transition Material

Power Generation and Transmission

In power plants and electrical substations, copper - aluminum transition material is used in busbars, switchgear, and other critical components. It ensures reliable and efficient transfer of electrical power from generators to transmission lines and helps maintain the stability of the electrical grid.

Industrial Electrical Systems

Industrial facilities often use a combination of copper and aluminum electrical equipment. Copper - aluminum transition material is employed in motors, generators, transformers, and control systems to establish secure and long - lasting electrical connections. Its ability to withstand harsh industrial environments and high electrical loads makes it an ideal choice for such applications.

Building Construction

In residential and commercial building construction, copper - aluminum transition material is used in electrical wiring systems, panel boards, and switchgear. It enables the safe and efficient distribution of electricity throughout the building and helps meet the growing demand for electrical power in modern buildings.

Electronics and Telecom

Copper - aluminum transition material is also finding applications in the electronics and telecom industries. It is used in the manufacturing of printed circuit boards (PCBs), connectors, and other electronic components. Its excellent electrical properties and lightweight nature make it suitable for use in high - speed electronic devices and communication equipment.

Conclusion

Copper - aluminum transition material has emerged as a valuable solution in the field of electrical systems. With its unique combination of properties, it addresses the challenges associated with connecting copper and aluminum components and offers numerous advantages in terms of electrical performance, corrosion resistance, weight, and cost. As the demand for efficient and reliable electrical systems continues to grow, copper - aluminum transition material is likely to play an increasingly important role in various industries. By understanding and utilizing this innovative material, engineers and manufacturers can enhance the performance and longevity of their electrical installations.