Copper Bus Bar Jointing Methods: Ensuring Reliability in Power Distribution

Copper Bus Bar Jointing Methods: Ensuring Reliability in Power Distribution

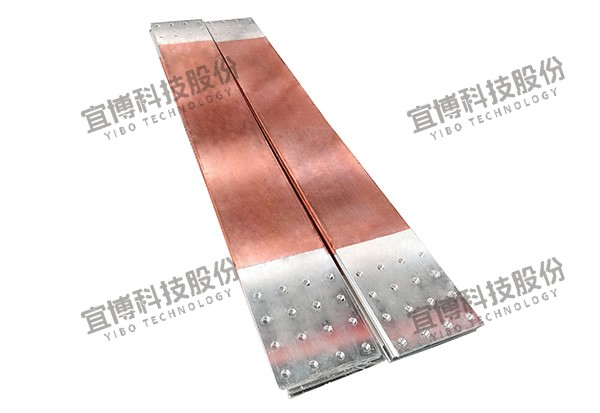

In electrical power systems, the copper bus bar serves as the critical artery carrying massive currents. Yet, its performance hinges on a often-overlooked detail: how effectively its joints are made. Faulty bus bar joints are notorious hotspots, leading to energy loss, equipment failure, and even catastrophic fires. Mastering copper bus bar jointing methods isn't just good practice – it's fundamental to system safety, efficiency, and longevity. Let's explore the key techniques and critical considerations.

Why Jointing is Critical for Copper Bus Bars

Copper boasts excellent conductivity, but a poorly made joint introduces significant resistance at the connection point. This resistance causes:

I²R Heating: Power loss converted directly into heat, accelerating degradation.

Hotspots: Localized overheating damaging insulation, oxidizing copper, and weakening the joint.

Increased Voltage Drop: Reduced voltage at critical loads.

Potential Failure: Thermal runaway, arcing, and connection failure under fault or high load.

Proper jointing minimizes contact resistance, ensures uniform current distribution, and maintains mechanical integrity.

Essential Copper Bus Bar Jointing Methods

Bolted Joints (The Most Common Method):

Principle: Mechanical pressure creates intimate metal-to-metal contact between overlapping bus bar surfaces using bolts, nuts, and washers.

Process:

Surface Preparation: Crucial Step. Joint surfaces must be meticulously cleaned using wire brushes (stainless steel, not abrasive), solvents, or specialized cleaning pastes to remove all oxides, grease, and contaminants. A dull copper surface is ideal.

Alignment & Overlap: Ensure precise alignment. Overlap length should generally be at least equal to the bus bar width. Chamfer sharp edges.

Application of Inhibitor: Apply a thin, even layer of copper bus bar jointing compound (anti-oxidant paste). This prevents re-oxidation, fills microscopic voids, and enhances conductivity.

Fastener Selection: Use high-strength bolts/nuts (e.g., Grade 8.8 or higher). Always use flat washers under bolt heads and nuts. Belleville (disc spring) washers or serrated lock washers are highly recommended to maintain pressure despite thermal cycling and prevent loosening.

Torque Tightening: Apply the manufacturer's specified torque in a cross-pattern sequence using a calibrated torque wrench. Under-torquing causes high resistance; over-torquing can deform the bar or strip threads. Re-torquing after initial heat cycles is often required.

Advantages: Simple, reversible, widely applicable, allows for disassembly.

Disadvantages: Requires precise torque control; susceptible to loosening over time; contact resistance depends heavily on surface prep and pressure.

Welded Joints (Permanent, Low-Resistance):

Principle: Melting and fusing the copper at the joint interface using heat. Creates a metallurgical bond.

Common Techniques:

TIG Welding (GTAW): Preferred for high-quality, precise copper bus bar joints. Uses a non-consumable tungsten electrode and inert gas shielding (Argon). Excellent control, clean welds. Requires high skill.

MIG Welding (GMAW): Faster than TIG, uses a consumable wire electrode and shielding gas. Suitable for thicker sections but can be spatter-prone.

Resistance Welding: Spot or butt welding using high electrical current and pressure. Fast but requires specialized equipment; joint area can be limited.

Friction Stir Welding (FSW): Emerging method, solid-state process creating very strong, ductile joints without melting. Excellent for high-integrity applications.

Process: Requires meticulous cleaning. Often needs pre-heating due to copper's high thermal conductivity. Precise control of heat input is vital to avoid grain growth and weakening in the Heat-Affected Zone (HAZ). Post-weld cleaning may be needed.

Advantages: Lowest possible contact resistance; permanent and mechanically robust; excellent current distribution; minimal maintenance.

Disadvantages: Requires skilled welders and specialized equipment; permanent (no disassembly); potential for HAZ weakening; higher initial cost.

Brazed/Soldered Joints (Permanent, Moderate Current):

Principle: Joining using a filler metal (solder or brazing alloy) with a lower melting point than copper, which flows into the joint by capillary action.

Differentiation:

Soft Soldering (<450°C): Uses tin-lead or lead-free alloys. Lower strength, suitable for lower current/voltage applications or attaching lugs. Requires aggressive flux.

Brazing (>450°C): Uses silver-based (Ag-Cu, Ag-Cd, Ag-Cu-P) or phosphorus-copper (BCuP) alloys. Stronger than solder, suitable for higher currents. Requires flux suitable for copper and high temperatures.

Process: Surfaces must be immaculately clean. Flux is applied to prevent oxidation. Heat is applied evenly to the joint area (torch, induction, furnace) until the filler metal melts and flows. Excess flux must be removed post-brazing to prevent corrosion.

Advantages: Good conductivity; permanent bond; can join complex shapes; lower temperature than welding (reduced HAZ).

Disadvantages: Filler metal conductivity is lower than copper; joint strength depends on filler; flux residue is corrosive if not removed; requires skill; not ideal for very high continuous currents or fault currents.

Compression/Crimped Joints (For Lugs and Connectors):

Principle: Mechanically deforming a connector (lug, splice) onto the prepared end of the bus bar using high pressure. Creates a cold-weld gas-tight seal.

Process: Clean the bus bar end and the inside of the lug. Insert the bar fully into the lug barrel. Use a calibrated hydraulic or mechanical crimping tool with the exact die set specified for the lug and bar size. Apply sufficient, controlled pressure.

Advantages: Reliable, consistent; good conductivity; relatively quick; no heat involved. Widely used for terminating cables to bus bars.

Disadvantages: Primarily for attaching lugs/connectors, not for bar-to-bar joints; requires specific, calibrated tooling; quality is highly tool-dependent.

Critical Factors for Successful Copper Bus Bar Jointing (Regardless of Method):

Immaculate Surface Preparation: The single most important factor. Oxide layers and contaminants are highly resistive. Clean until bare, bright copper is achieved immediately before joining. Use proper tools (non-embedding wire brushes, approved solvents/pastes). Protect cleaned surfaces.

Proper Contact Area: Ensure sufficient overlap (bolted) or penetration (welded/brazed). Follow engineering guidelines or standards (e.g., IEC 61439).

Controlled Pressure/Heat: Use calibrated tools for torque or crimping. Control welding/brazing heat input precisely to avoid damage.

Corrosion Protection: Use appropriate jointing compound (bolted), flux (solder/braze), and/or protective coatings post-joining. Prevent galvanic corrosion if dissimilar metals are nearby.

Thermal Cycling Considerations: Design joints to withstand expansion/contraction. Use Belleville washers on bolted joints. Ensure welded/brazed joints have adequate ductility.

Adherence to Standards: Follow relevant international (IEC, IEEE), national (NEC, BS), and manufacturer specifications rigorously.

Choosing the Right Jointing Method:

Bolting: Best for field installations, maintenance access, and non-permanent connections where high skill welding isn't available. Requires disciplined surface prep and torque procedures.

Welding (TIG): Ideal for permanent, ultra-low resistance joints in critical, high-current applications (e.g., switchgear main bus, substations). Requires high skill and equipment.

Brazing: Good permanent solution where welding heat is excessive or for complex joints. Stronger than soldering.

Soldering: Suitable for low-current signal bars or attaching small components.

Crimping: Standard for attaching cable lugs to bus bar connection points.

Conclusion: Reliability Starts at the Joint

Ignoring copper bus bar jointing methods is gambling with system integrity. Whether you choose bolting, welding, brazing, or crimping, success is defined by meticulous surface preparation, precise execution according to standards, and an understanding of the method's strengths and limitations. Investing time and resources in mastering these techniques pays dividends through reduced energy losses, enhanced safety, predictable performance, and extended equipment life. Remember, the strongest copper bus bar is only as reliable as its weakest joint. Prioritize best practices in jointing for a robust and efficient power distribution system. For critical applications, always consult detailed standards and consider involving qualified specialists for welding or complex brazing operations.