The Essential Guide to Flexible Copper Connection Types for Modern Electronics

Flexible copper connections serve as critical components in power distribution systems across industries. Their ability to absorb vibrations, accommodate thermal shifts, and enable compact designs makes them superior to rigid alternatives in advanced electrical applications.

Core Flexible Copper Connection Types

Braided Copper Straps

Woven copper wire constructions deliver exceptional flexibility and vibration resistance. Available in bare, tinned, nickel-plated, or silver-plated variants, they excel in harsh environments. Tinned versions remain widely adopted due to effective corrosion resistance. Key applications:Transformer and switchgear connections

Electric vehicle battery interlinking

Industrial machinery grounding

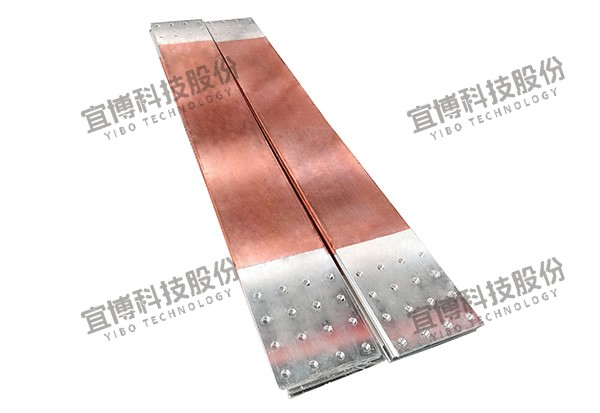

Laminated Flexible Busbars

Multi-layer copper sheets bonded with specialized insulation achieve high current capacity with minimal electromagnetic interference. These significantly reduce system weight while improving thermal performance in applications like:EV battery packs

Data center power distribution

Renewable energy installations

Foil Connectors

Ultra-thin annealed copper sheets provide maximum flexibility for space-constrained applications. Dominant uses include:Consumer electronics (smartphones, laptops)

Foldable device hinges

High-frequency antenna systems

Cable Assemblies

Integration of flexible conductors with protective jackets serves demanding environments:Robotic systems requiring millions of flex cycles

EMI-sensitive medical and aerospace equipment

Industry Applications

| Sector | Key Implementations |

|---|---|

| Transportation | EV batteries, charging systems |

| Clean Energy | Solar panel wiring, wind turbine circuits |

| Digital Infrastructure | Server racks, UPS backups |

| Automation | Robotic arms, CNC machinery |

Selection Criteria

Match connection types to applications using these parameters:

Current Requirements: Braided straps for moderate loads; busbars for high-capacity

Flexibility Needs: Foil connectors for tight bends; straps for multi-directional movement

Environmental Factors: Plated variants for corrosive conditions

Certifications: Regional compliance standards for global deployment

Comparison Table

| Type | Typical Current | Flexibility | Common Applications |

|---|---|---|---|

| Braided Straps | Moderate | High | Grounding, industrial equipment |

| Laminated Busbars | High | Medium | EVs, power systems |

| Foil Connectors | Low | Very High | Electronics, compact devices |

| Cable Assemblies | Medium-High | High | Robotics, specialized machinery |

Emerging Innovations

Integrated Monitoring: Next-gen connections with real-time performance tracking

Eco-Materials: Sustainable copper alloys reducing environmental impact

Advanced Insulation: New dielectric materials enabling higher frequency transmission

Industry Outlook

Flexible copper connections are transforming from passive elements to active enablers of technological progress. As electrification accelerates across sectors, selecting optimal connection types—whether braided, laminated, or foil-based—becomes crucial for system reliability and efficiency. Manufacturers focusing on modular designs, durability enhancements, and environmental compliance will lead market evolution.